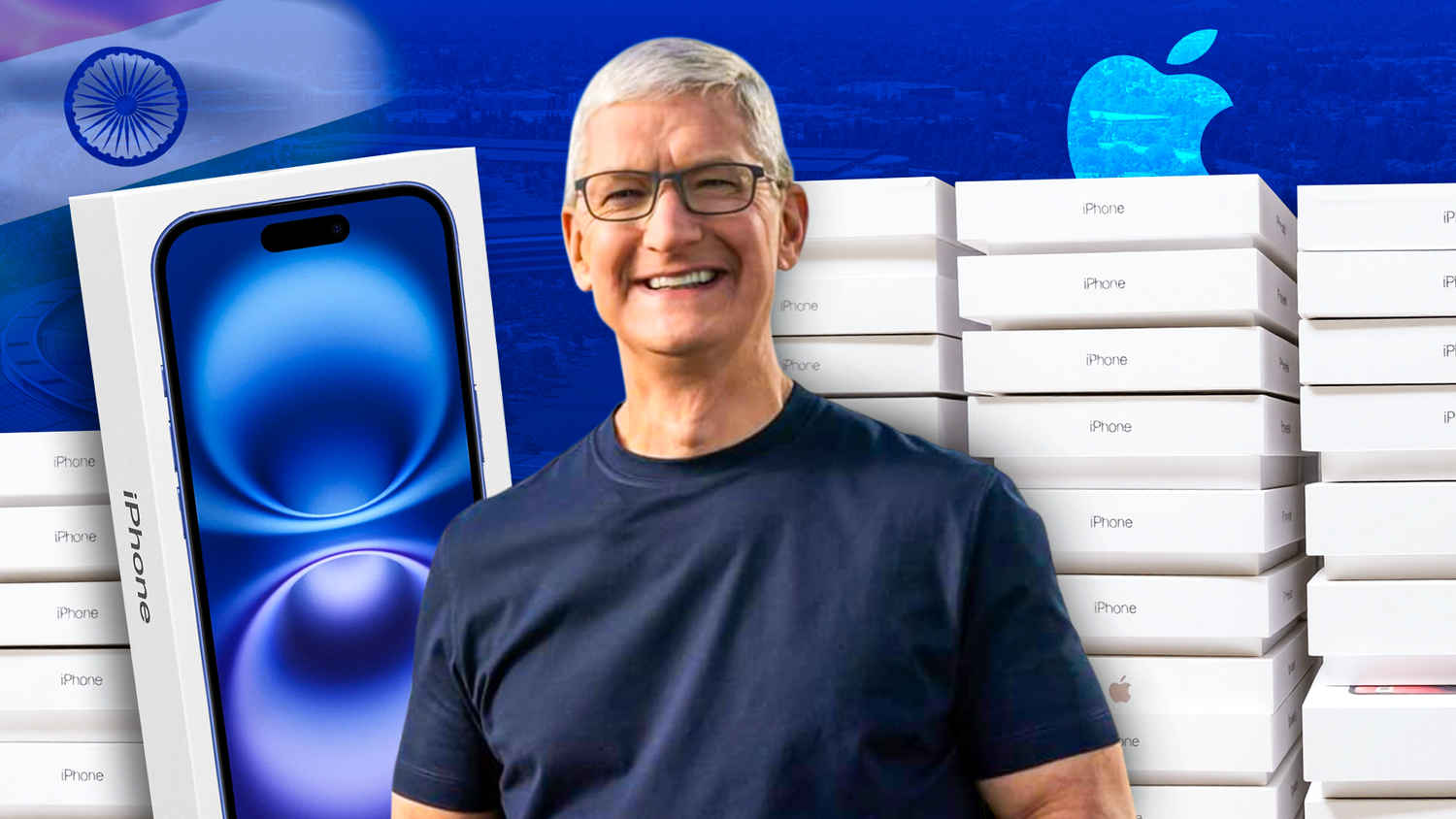

Made in India iPhone: How India’s saving Apple from Trump’s China tariffs

In the final week of March, five cargo planes departed India in quick succession. Their payload? Thousands of freshly manufactured iPhones, bound for warehouses across the United States. The urgency was unmistakable as Apple was racing against the clock for an unusual logistical operation that was completed in just three days.

On April 5, a minimum of new 10% reciprocal tariff announced by U.S. President Donald Trump went into effect, targeting electronics imported from key Asian manufacturing hubs. For Apple, which relies heavily on China for the bulk of its iPhone production, the new duties formed a part of a wider escalation of US-China trade tensions, which could have meant a potential cost surge of $300 per device, as per TechInsights’ Wayne Lam. But India offered a relatively safer port.

Why did Apple ship iPhones from India to US?

The flights from India weren’t just a logistics exercise. They were the first tangible sign of a new chapter in Apple’s production playbook. You see, for years, China has been the undisputed epicentre of iPhone manufacturing, thanks to its vast supplier networks, labour scale, and government incentives. But, the US-China tariff war, revived under Trump’s renewed campaign rhetoric, has forced the tech giant to reconsider its overdependence on one region.

Now, India is stepping into the frame, not as a supplementary hub, but increasingly as a primary alternative.

According to senior government officials, the March shipments were aimed at preemptively stockpiling inventory in the US ahead of the tariff hike. Apple’s U.S. warehouses are now reportedly stocked for months, cushioning the company from immediate price shocks. But this is only a temporary fix.

The broader plan is more ambitious: ramp up Indian production for the US market while letting Chinese factories cater to other regions like Europe, Asia, and Latin America. “India’s factories will be increasingly used to ship only to the US. Demand in other markets such as Europe, Latin America and even Asia will now be catered to from the China factories,” a senior industry executive confirmed to Times of India.

Also Read: Tim Cook says Apple will remain bullish in India

About tech tariffs and future tradeoffs

Under the revised policy, Chinese goods face a 104% tariff, including a recent 50% increase, while Vietnamese goods are subject to 46%. Indian exports, by contrast, are levied at 26%.

This tariff gap between India and China makes Indian-made iPhones significantly more competitive in the US, and not just in theory. According to Bank of America analyst Wamsi Mohan, Apple is expected to manufacture 25 million iPhones in India in 2025, up from roughly 15 million last year. Of those, nearly 10 million units initially meant for domestic sale may now be redirected to meet up to 50% of US demand.

Apple has begun using production at its Indian factories to ship iPhones directly to the US, a shift from its earlier strategy where most of its exports to the US came from China.

iPhones in India are primarily operated by Taiwanese giant Foxconn and the Tata Group (which acquired Wistron and Pegatron’s Indian assets) and are still scaling up. The industry official added that if Apple forgoes establishing new production bases in countries like the UAE, Saudi Arabia, or Brazil which attract only a 10% tariff to the US, but infrastructure is nascent, there could be significant expansion in India. This would involve fresh investments by Foxconn and Tata, and potentially drive iPhone shipments to the US beyond the estimated $10 billion for the current fiscal year.

For now, Apple’s immediate concern has been to avoid passing higher costs to consumers. Apple’s review of tariff structures across manufacturing bases is ongoing.

India’s growing tech manufacturing hub

India’s appeal lies not just in tariffs. Since 2017, Apple has steadily deepened its footprint in the country, initially assembling older iPhone models for local sale to dodge import duties. Over time, the scope has widened to include newer flagships and AirPods.

The “Made in India” label now carries strategic weight, especially as the company braces for an extended tariff war. While assembling an iPhone in India still requires components imported from China and elsewhere, the final assembly shift is enough to secure tariff relief under US customs laws.

Currently, Apple accounts for the bulk of India’s estimated $9 billion in smartphone exports to the US. The company is also evaluating the long-term implications of tariffs for its global supply chain while seeking a possible exemption from the new duties, a strategy previously achieved by CEO Tim Cook during Trump’s earlier term.

India’s rising importance in Apple’s global production network coincides with a milestone for the country’s electronics industry. Union Minister for Electronics and IT, Ashwini Vaishnaw, announced earlier this week that smartphone exports from India surpassed ₹2 lakh crore for the first time in FY25, which is a 54% increase compared to the previous fiscal year. The growth is largely credited to the government’s Production-Linked Incentive (PLI) scheme, which has also helped drastically reduce imports. Almost 99% of smartphones used today in India are manufactured locally.

Apple’s iPhone supply chain contributed nearly 70% of India’s total smartphone exports, according to the India Cellular and Electronics Association (ICEA). While the ICEA had projected exports to reach $20 billion (approximately ₹1.68 lakh crore) in FY25, actual figures exceeded these expectations by a wide margin.

As global value chains continue to integrate with India’s manufacturing base, the country’s role in global electronics production is expanding rapidly. The surge in exports is also creating significant employment opportunities and drawing Indian MSMEs into the global supply ecosystem.

It’s not just Apple, as Samsung also bets big on India

Apple isn’t alone. Samsung, whose Vietnamese operations export over $55 billion worth of electronics annually, is also weighing the Indian option. With Vietnam now subject to a 46% tariff, Samsung may prefer to ship from India, even at 26%, while Vietnamese authorities continue discussions with the US for a proposed zero-duty agreement. Samsung’s Noida factory already manufactures high-end models such as the Galaxy S25 and Fold series and is being closely evaluated as an alternative export base to the US.

Officials involved in negotiating a Bilateral Trade Agreement (BTA) between India and the US are aware of these evolving dynamics and are factoring them into ongoing discussions aimed at expanding India’s role in global electronics manufacturing.

The current production adjustments are seen as a stopgap while tariff negotiations continue. Apple has not made any immediate pricing changes in India or elsewhere as a result of the new tariffs. For now, the five planes that left Indian tarmacs in March may symbolize more than a supply chain shift, as Apple’s gamble could well become its long-term strategy.

Read More: Sam Altman’s ChatGPT openly challenges DeepSeek, Llama: Open source AI war begins

Siddharth Chauhan

Siddharth reports on gadgets, technology and you will occasionally find him testing the latest smartphones at Digit. However, his love affair with tech and futurism extends way beyond, at the intersection of technology and culture. View Full Profile