In Depth: A peek inside your display

Ever wondered what makes your display tick?

Commercial display technologies have seen a massive revolution in the past decade. While the early 2000s saw a rise in the use of CRT screens, right up to 2006, it has since been overtaken by other cheaper and safer technologies like plasma screens, LCD displays and many more. Current technology mainly differs on certain pressure points like contrast ratios, color gamuts, reproduction fidelity, lifespan and energy expedition. While clever marketing on behalf of giants such as Sony, Samsung and Panasonic may lead you to believe in the merits of certain technologies over others, it’s best to make an informed choice about what you’re really going to be investing in before taking the plunge. Curious? Read on…

Survey

SurveyEvery display technology has one common backing principle. Based on the information in a video signal, the display lights up thousands of tiny dots (called pixels) with a high-energy beam of electrons. In most systems, there are three pixel colors — red, green and blue — which are evenly distributed on the screen. By combining these colors in different proportions, the television can produce the entire color spectrum. However, having said this, each technology makes use of different materials for its pixels, with new and more energy efficient methods, hence requiring a slightly more in-depth understanding of individual tech. If you’re still undaunted, go ahead. You should find all the information you need to help you out.

Plasma Screens

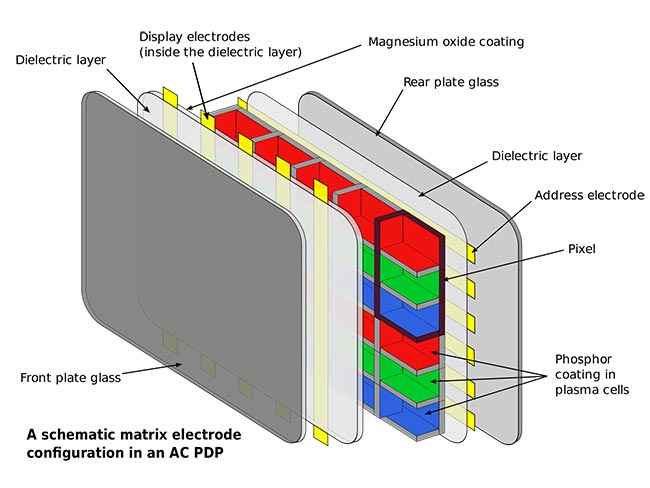

Let’s start with plasma screen, which is probably the oldest of the lot we’ll be discussing. The internal structure of the display screen involves gases like xenon or neon contained in thousands of cells in a grid like structure behind the screen, sandwiched between two glass plates. Each cell is a pixel, which has three subpixels. These subpixels are basically three different coloured phosphors, which blend together when excited to create the required colour.

Cross section of a typical Plasma panel

The main advantage of plasma screens was the contrast ratio, considered one the best in the industry. Because plasma is able to provide deeper blacks and brighter whites, it has a high colour gamut. In addition, better viewing angles and lower backlighting problems due to the absence of a backlight made it a runaway hit. Alas, as enticing as this technology sounds, it has been discontinued by the biggies like Samsung and Panasonic. A big reason is burn-in due to static images, caused by the phosphors wearing out, further leading to a shorter life span. And since a plasma screen involves the use of a heavy electrode grid, it gets heavier for larger display sizes, with almost no corresponding increase in resolution.

Liquid Crystal Displays (LCDs)

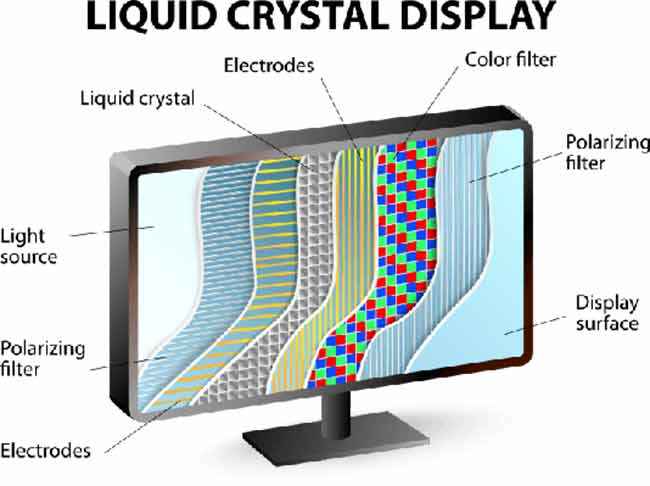

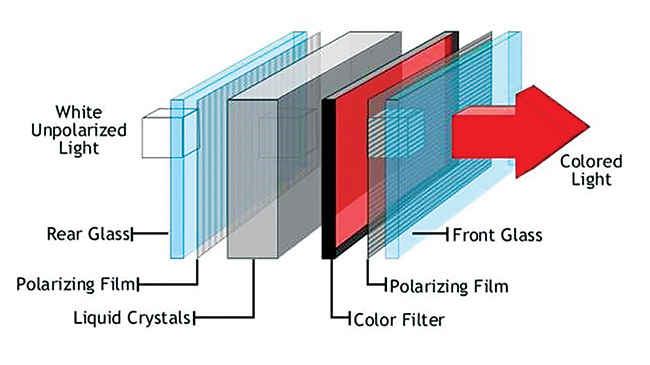

The plasma display was followed up by the Liquid Crystal Display. It works with liquid crystals, which have intermediate properties between solid and liquid, and change optical properties when exposed to electrical current. In LCDs, the internal structure involves a layer of liquid crystals being positioned between two polarisers, which an average reader can assume to be a device that allows light to pass at certain angles. Most of the common LCDs work when the crystals change their orientation from twisted to straightened (this particular kind of liquid crystal display, in which the crystals are twisted in their unperturbed orientation, is called a twisted nematic display), which changes the opacity of the crystals to transparent.

If we apply an electric charge to the liquid crystal molecules, they untwist. When they straighten out, they change the angle of the light passing through them so that it no longer matches the angle of the top polarizing filter. Consequently, no light can pass through that area of the LCD, which makes that area darker than the surrounding areas. An LCD that can show colors must have three subpixels with red, green and blue color filters to create each color pixel.

Cross section of a typical LCD panel

High-resolution color displays, such as modern LCD computer monitors and televisions, use an active-matrix structure. A matrix of thin-film transistors (TFTs) is added to the electrodes in contact with the LC layer. Each pixel has its own dedicated transistor. Active-matrix addressed displays look brighter and sharper than passive-matrix addressed displays of the same size, and generally have quicker response times, producing much better images.

Since these crystals have no internal light of their own, unlike the phosphors in plasma screens, a white fluorescent backlight is used for coloured LCDs, which is positioned behind the screen. When someone refers to an LCD TV, they usually mean a CCFL (cold-cathode fluorescent lamp) backlit LCD screen.

Through the careful control and variation of the voltage applied, the intensity of each subpixel can range over 256 shades. Combining the subpixels produces a possible palette of 16.8 million colors. These color displays take an enormous number of transistors.But since transistors are known to be fickle and easily damageable devices, one major problem with LCD screens is dead pixels because of defective transistors. This, coupled with problems involving viewing angles, glare levels and contrast ratio, outweigh its numerous advantages related to brightness, power consumption and sharpness of the projected image. Even so, a large number of computer laptop screens, display monitors and smaller consoles use this tech today.

Light emitting diodes (LEDs)

Jumping on to more recent and widely used technology, we have LED screens, which work similar to LCDs. You still have your multiples layer including two polarisers and a layer of liquid crystals. The only real difference lies in using LEDs to backlight the screen instead of white fluorescent tubes, as in LCDs. After the discovery of white light LEDs, their use in display screens became more widespread and led to the development of the LED screen as we know it today. However, unlike in an LCD, the LED can be placed at various positions behind the screen to change effectiveness and viewing angles. You have your edge lit LED screens, with a row of LEDs around the rim of the screen, as seen commonly in mobile phone displays. Most large screen TVs and displays use the full array backlighting, with a full layer of LEDs behind the screen. However, this forces one to give up control of individual LEDs. That was offset by the introduction of dynamic backlights, where individual LEDs could be controlled to dim the screen in certain spots, lending even higher contrast to the pictures. Many sets use white LED edge lighting to shine light across the display. RGB LED-backlit sets, on the other hand, provide improved color. However, since the technology still uses the liquid crystals of LCDs, there is no real advantage apart from the weight and thickness of the screen. Hence, the main innovation lies in the use of OLEDs, which we cover next.

Cross section of a typical LED panel

The new generation: Organic LEDs

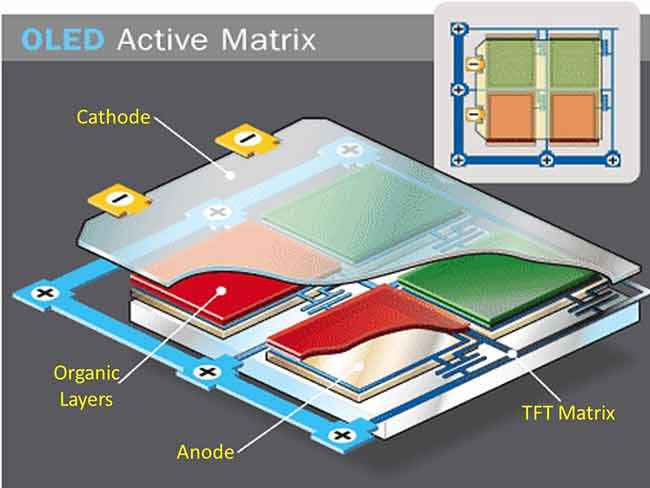

The use of OLEDs – organic LEDs – is ushering in a different era of largely scalable displays that consume almost half the power conventional LED screens and LCDs do. While an OLED is similar to an LED, it uses a layer of organic molecules that have the ability to become illuminated when the molecules are ionised. Unlike LCD (Liquid Crystal Display) technology, OLED does not require backlighting to function. The internal structure of an OLED screen is basically a layer of this organic material sandwiched between an anode and cathode, with another layer of conducting material to boot. The anode, which is positively charged, pulls out electrons from the conducting layer, leaving the organic layer to be sandwiched between two layers of positively (the conducting layer) and negatively charged (cathode) particles. Hence, this eliminates the need for any backlighting, reducing the weight and thickness of the screen by half, and further cutting down on power expenditure.

The most commonly used OLED screen is the AMOLED – an active matrix OLED. Except for the technique of powering the LED’s (sub-pixel). AMOLED cells contain the above described structure of an OLED screen arranged in small sheets (pixels), sandwiched between a larger cathode sheets and integrated into a TFT (thin film transistor) matrix (the one that is used in numerous LCDs). The TFT matrix controls which pixels is to be illuminated, by controlling the current flow for each pixel, thus functioning as a sort of switch. AMOLED screens are used for a large number of mobile screen displays such as that of the Nexus 6 and Samsung Note and Galaxy series, and in numerous tablets and digital camera screens.

Cross section of a typical OLED panel

All in all, AMOLED displays provide a better colour gamut, more accurate black reproduction and higher contrast, lesser weight and thickness with reduced power consumption and a wide variety of viewing angles. And while regular AMOLED screens have reduced brightness and present problems when viewed in sunlight, a new variety called super AMOLED screens changes that by reducing the distance between layers. However, AMOLED displays are still expensive, and efforts are on to reduce the cost of this widely applicable and versatile technology.

Digitising everyday books: eInk

Another widely used technology is eInk, used in many e-readers such as the Kindle. Instead of a conventional LCD screen, it uses a new material called microcapsules, that contain black and white negatively and positively charged particles respectively. A layer of electrodes beneath the microcapsules help change the orientation of the coloured charges, making them work in tandem to render text and images seen on these screens.

Unlike conventional backlit flat panel displays that emit light, electronic paper displays reflect light like paper. The absence of a backlight means that most of these screens cannot be read without an external light source, just as with regular novels and newspapers. This provides better viewing angles and less glare, helping you achieve that perfect reading experience.

Your perfect display highly depends on your requirements and budget (the biggest factor of them all). Take a while, analyse the specs of your preferred model and take a well-informed decision as to whether you genuinely need to shell out an extra 10k for that new 4K HD display that probably won’t end up meeting your expectations. Happy shopping!

This article was first published in the March 2016 issue of Digit magazine. To read Digit's articles first, subscribe here or download the Digit e-magazine app.